APRON & HANGAR SERVICES

State-of-the-Art Aircraft PreConditioned Air Systems

PRECONDITIONED AIR SYSTEM

Cooperating with major aircraft manufacturers, Consultants, Airlines and user groups, Avicorp can assure you of a design meeting customer expectation for aircraft environmental control.

Avicorp focuses on system performance, efficiency and reliability. Its engineering staff addresses total system design, including central chiller plants and distribution networks. Avicorp’s problem solving approach led to the development of the hybrid CW + DX design, and the introduction of the Avicorp DXBoost® product line. With the popularity of MARS gates, Avicorp met the challenges of serving two aircraft from the same unit, providing different airflow, pressure and temperature characteristics.

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

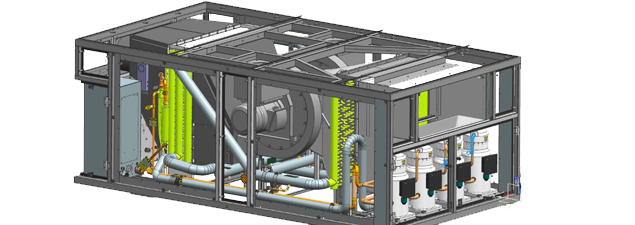

DXBoost® PCA

The current Avicorp staff members introduced the DXBoost® concept in 1982. The design has matured and improved and is now the most preferred design. Requiring only standard CW supply / return and reduced electrical support, the system is capable of supply sub-freezing air in the most challenging environments. A perfect solution for installation in hangar equipment rooms, the units are also adapter for mounting under the passenger loading bridge.

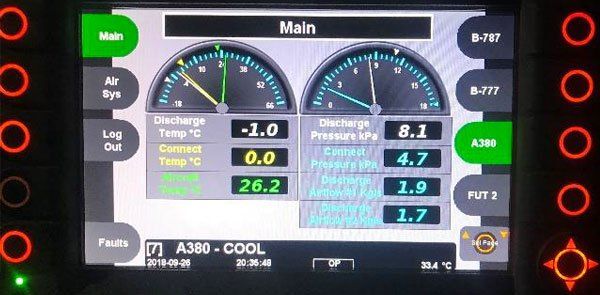

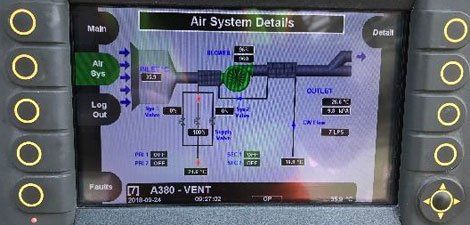

PCAir HMI Interface

Recent industry mandates specify both maximum airflow and pressure for each aircraft. Performance is limited to “whichever condition occurs first”. Pressure and temperature are measured at the aircraft connector. Both can be monitored and controlled to above freezing temperature for the Boeing product, and subfreezing for the Airbus product. The system offers a complete array of display screens, displaying status in both graphic and detailed text. Assuring compliance with IATA AHM 974 and 997, they system can be adapter to all new units, as well as adapter to units already in service.

Accurate Airflow Measurement

Measured airflow in KG/S with Pressure and Temperature measured at the aircraft adapter. Note measurement of each hose is available to the operator. The PCAir unit’s internal PC Controller is programmed to maintain ex- acting performance, Ridgely adhering the published aircraft limitations.

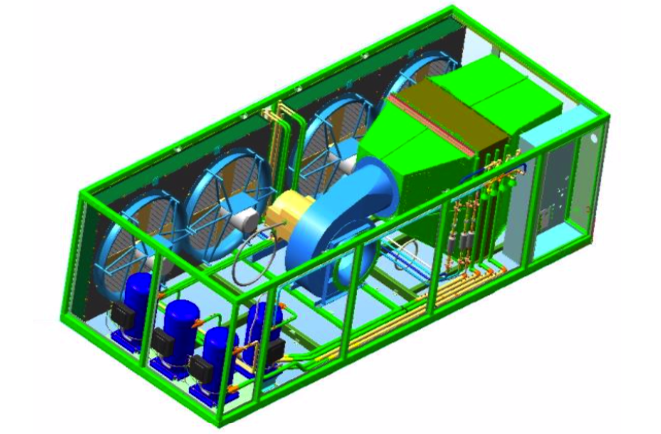

Air Cooled PCAir Units

Available in either bridge mount or ground mount configurations, the air cooled DXUnit is a universally accepted PCAir solution. Avicorp supplies units specifically selected for the harsh Middle East environment. Units are sized to provide delivered air at -8°C from the unit’s outlet(s). State-of-the-art controls with vivid graphics control and display pressure, temperature and mass flow measured at the aircraft connector. Utilizing environ- mentally sensitive refrigerants, VFD support of blowers and fans, the unit has proven itself superior to all others.

DXUnit: 120 Refrigerant Tons

Airflow: 4.2 Kg/S (* Up to)

Static: 12,500 Pa (*)

Discharge: -10°C (*)

Ambient: 46°C DB / 29°C WB

Mounting: PBB Trailer or Ground

Electrical: 50/60 Hz 380-480 VAC

Amperage: 400 Amps

Centralized PCAir System

The classic centralized PCAir system remains viable with Avicorp’s unique system enhancements. The classic single loop system featured distributed EGW at -7°C / -2°C supplied to specialized AHU’s. This allowed for the -4.5°C discharge air required to maintain +2°C at the aircraft. Avicorp enhancements feature a High ΔT (delta T) loop. Central plant cooling utilizes direct CW to EGW heat exchangers for initial cooling, then traditional EGW chillers for secondary cooling of the loop.

Initial equipment costs are reduced by ±50%, system efficiency is improved with lower EGW flows and 50% of the cooling provided by the facility’s low KW/Ton chilled water system.

The AHU is unique with the blower located between the coils, which greatly enhances performance. Dual Loop / dual coil systems are also provided. This allows ±70% of the cooling to be provided by building chilled water and ±30% by a dedicated EGW loop. The AHU features a unique design with the blower located after the first stage coil. The second and third stage coils allow for supply of sub-freezing air. The design improves efficiency ±35% and performance by ±15% because of a reduction in the need for defrosting.

Centralized PCAir System

Avicorp’s In Ground Systems (IGS) are unique, modular, factory assembled and tested, aircraft service pits. Eliminating the need for cast in place concrete structures, major benefits are enjoyed. Pit drainage and sump pumps are built-in. Components are all populated, in the factory, and shipped complete to the site. Rust free enclosures offer a lifetime of trouble-free service. The counterbalanced lids meet all load requirements. The hatch design allows for minimal alignment demands. In the case of damage from ground equipment, gates can be returned to immediate ser- vice, whereas the Pop-Up design can cause major operational problems.

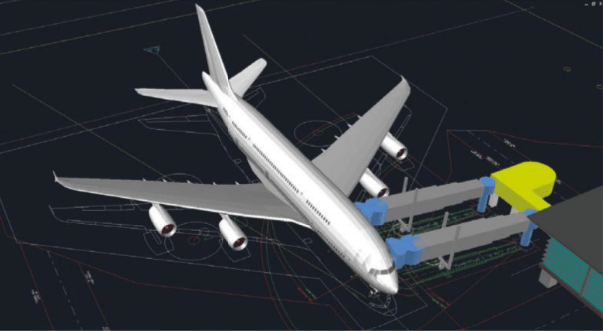

Avicorp Middle East DXBoost

Solves the MARS Gate Dilemma

Avicorp is pleased to announce that the US Patent and Trademark Office has granted patent rights for its design of an Independently Controlled Dual Outlet (PCA) Aircraft Air Unit. The unit is particularly well suited for MARS (Multiple Aircraft Ramp System) aircraft stands. MARS is an innovative bridge layout arrangement allowing for two boarding bridges to service one single jumbo aircraft or two smaller, narrow body aircraft at the same gate”. Now it is possible to deliver air at different temperature, pressure and airflow to two (2) different aircraft parked at the same stand. The design is based on the CW+Hybrid design philosophy of the DXBoost®, a registered trademark of Avicorp.